Building your golf cart frame is an exciting project that allows you to create a custom cart from the ground up. A well-designed frame is the foundation for a golf cart that performs well and stands the test of time. Whether building a cart for leisurely rides around your neighborhood or something more utility-driven, understanding the basics of frame construction is essential.

Flamingo Custom Carts in Atlanta is an excellent resource for those who may want guidance or custom options beyond a DIY approach. Their expertise in high-quality golf cart customization can be leveraged at any stage of your project, from providing premium parts to assisting with the finer details of design.

Let’s Understand the Basics

🔧 What Is a Chassis on a Golf Cart?

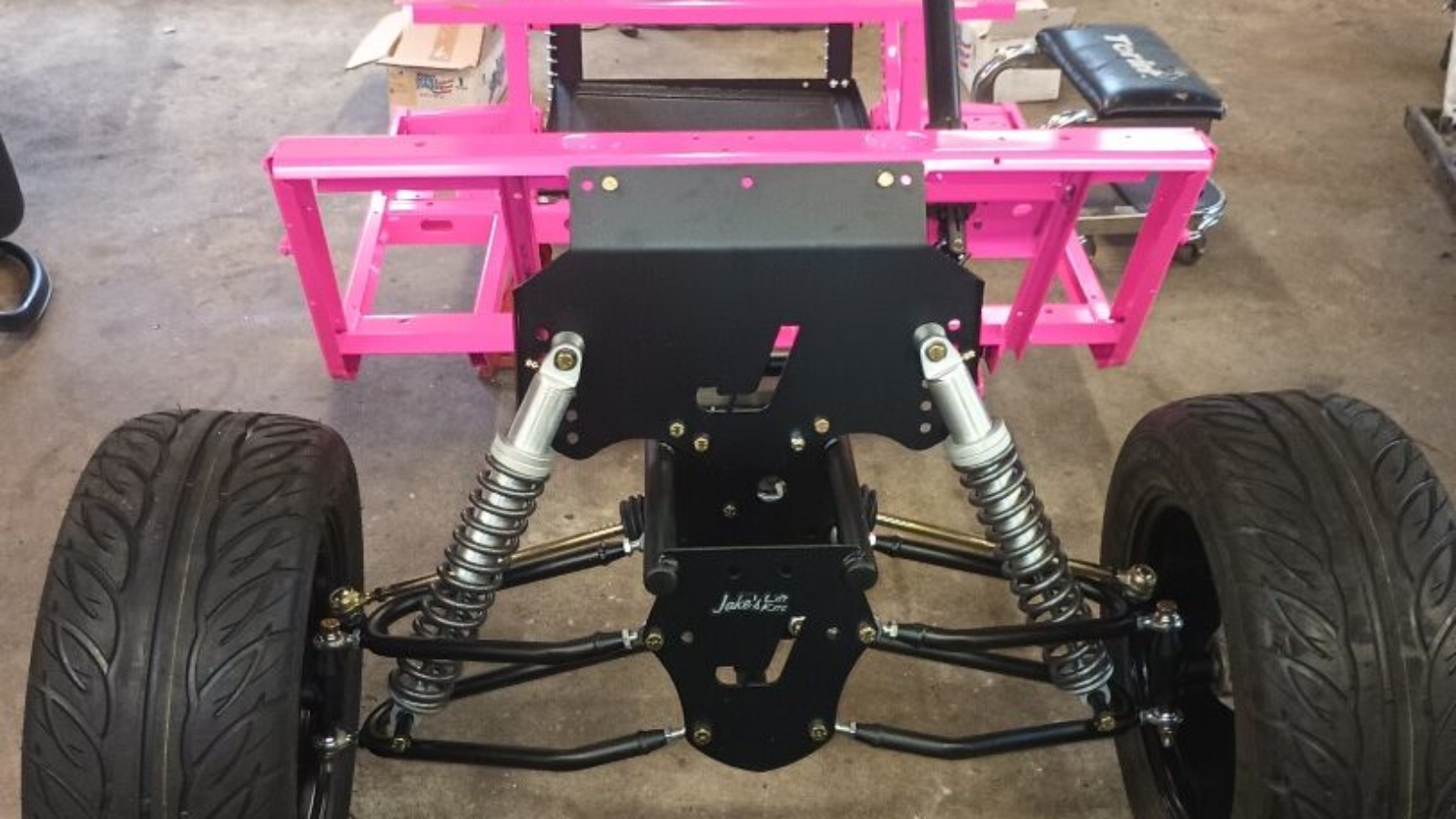

The chassis is the foundation of your golf cart—it’s the structural frame that supports everything from the suspension to the body panels, wheels, and seating. Think of it as the skeleton that holds your ride together. A well-built chassis ensures durability, balance, and safety, whether you’re cruising your neighborhood or tackling rougher terrain.

In the images featured on this blog, you’ll see how the frame starts as welded steel or aluminum tubing—measured, cut, and assembled for strength and stability. If you’re planning a build from scratch or customizing your current ride, a strong, properly aligned chassis is where it all begins.

Whether you want to replace a damaged frame or start your own cart project, our steel and aluminum chassis options come professionally welded and ready for accessories, axles, batteries, and more. Browse our inventory or speak with our team to find the perfect frame that fits your vision.

Moving forward to building your golf cart from scratch to a finished body

Step 1: Plan Your Design

The first step in building a golf cart frame is to outline the purpose and requirements for your cart. Consider the following:

- Usage: Will it be a light, recreational cart or a heavy-duty one for work purposes?

- Size: Decide on the frame dimensions, keeping in mind where the cart will primarily be driven.

- Weight Capacity: Think about the number of passengers and any additional weight from accessories.

Pro Tip: For custom design consultations, Flamingo Custom Carts offers expert insights to help you design a frame that meets your specific needs. Their team can assist with everything from layout suggestions to space optimization.

Step 2: Gather Materials and Tools

A strong, durable frame requires the right materials. Aluminum and steel are commonly used for golf cart frames, each offering its advantages:

- Aluminum: Lightweight, resistant to rust, and easier to handle, making it ideal for lighter, more maneuverable carts.

- Steel: Stronger and heavier, better suited for carts that need to carry more weight or withstand rougher terrain.

Materials List:

- Steel or aluminum pipes (for the main frame)

- Welding tools

- Metal saw

- Bolts and nuts

- Measuring tape

- Protective gear (gloves, safety goggles, etc.)

Step 3: Build the Frame Structure

Now, it’s time to build the frame’s base structure. This involves cutting the metal to the correct dimensions and assembling the main body of the frame.

- Measure and Cut: Using your design plan, measure and cut the metal pipes or bars to form the frame’s outline.

- Weld the Pieces Together: Carefully weld the pieces at each joint to create a sturdy structure. Make sure each weld is solid to prevent weak points in the frame.

- Test for Stability: Once welded, ensure that the frame is even and stable. If adjustments are needed, make them now to avoid alignment issues later.

For those who aren’t confident in their welding skills, Flamingo Custom Carts can help with frame assembly. Their team of certified technicians specializes in custom modifications and can build a sturdy, professionally welded frame tailored to your specifications.

Step 4: Install Suspension and Steering Components

Suspension and steering systems are essential for a smooth ride and optimal handling. Depending on your needs, you can opt for a basic setup or a more advanced suspension system.

- Suspension: Leaf springs are commonly used, but coil-over suspensions offer more flexibility and comfort.

- Steering Column: Install a steering column that suits your frame dimensions and layout. Position it in a way that allows comfortable handling.

Flamingo Custom Carts provides high-quality, compatible parts for both suspension and steering systems, offering options that can enhance comfort and handling. They stock a variety of suspension components suited for different terrains, so whether your cart is for smooth rides or rugged paths, they can provide the right parts.

Step 5: Add the Axles, Wheels, and Brakes

The axle and wheels are crucial elements of your cart’s frame structure. These components determine the ride quality, stability, and safety of your custom-built golf cart.

- Attach Axles: Install the axles based on the dimensions and layout of your frame. Ensure they’re securely fastened to avoid misalignment.

- Install Wheels: Choose wheels that are suited to the primary terrain you’ll be driving on, whether turf-friendly tires or off-road options.

- Add Brakes: Attach a braking system to ensure safe stops. Hydraulic disc brakes are a great option for more powerful carts, while traditional drum brakes work well for lighter builds.

At Flamingo Custom Carts, you’ll find a selection of premium wheels, axles, and braking systems. They offer consultation on compatible parts and can help with installation, ensuring your cart meets the highest standards of performance and safety.

Step 6: Finish with Custom Add-Ons and Accessories

One benefit of building your golf cart frame is the freedom to add personalized touches. Here are some customization options to consider:

- Custom Paint and Finishes: Add a durable paint or powder coating for aesthetics and protection.

- Seating and Upholstery: Choose comfortable, stylish seats that suit the purpose of your cart.

- Lighting: Install LED, under-glow, or headlights for enhanced visibility and style.

- Other Accessories: Bluetooth audio, cup holders, and other custom features can add convenience and flair.

DIY vs. Professional Assistance approach to building a golf cart frame

| Build Step | DIY Approach | Professional Assistance (Flamingo Custom Carts) |

|---|---|---|

| 1. Design Planning | Research dimensions, materials, and weight capacity requirements for your frame. | Offers design consultations to align your frame build with your specific needs and intended usage. |

| 2. Material Selection | Choose materials like aluminum or steel based on weight and durability. | Provides guidance on the best materials for durability, performance, and budget. |

| 3. Welding and Assembly | Requires welding tools, skills, and safety knowledge; mistakes can impact frame stability. | Certified technicians handle professional welding and ensure a structurally sound, high-quality frame. |

| 4. Suspension and Steering Installation | Gather suspension and steering components and follow alignment best practices. | Supplies high-quality suspension and steering parts suited to your design and usage. |

| 5. Axles, Wheels, and Brakes | Source compatible parts and ensure they fit securely for stability and safety. | Offers premium, compatible options and handles installation for improved stability and safety. |

| 6. Customization (Paint, Accessories) | DIY paint and basic accessories; limited options for advanced add-ons. | Provides custom paint finishes, seating, lighting, and unique accessories that align with your vision. |

Flamingo Custom Carts is a one-stop shop in Atlanta for high-quality accessories and customization options. They provide everything from custom seats and steering wheels to lighting options that make your cart stand out. If you need assistance with final assembly, their team can also help install these accessories to create a polished, professional finish.

Conclusion

Building your golf cart frame is a rewarding project that lets you craft a cart perfectly suited to your needs and style. From selecting materials and welding the structure to adding final customizations, each step allows you to create a unique vehicle. If you need premium components, expert consultation, or high-quality accessories, Flamingo Custom Carts in Atlanta is the perfect partner to guide and assist you through the process.

Visit Flamingo Custom Carts to explore their offerings and leverage their experience to bring your custom golf cart vision to life.

📍 Based in Atlanta | Serving all of Georgia

🔗 Explore Frames & Parts

Add a Comment